Lower & Longer # 2 :

October 29, 2022

Reduced air Volume - Repeated

To place the two ‘Low Air’ experiments in overall

context, the typical smelt :

- uses 22 - 25 kg ore analog

- uses air input in the range of 800 + LpM (in 25 cm ID furnace)

- charcoal consumption rates in the range of +/- 8 minutes per kg

- expected bloom weight roughly 5 - 6 kg

- production yields roughly 20 - 25 %

Recently, a higher quality Omega

HHF 1001 'hot wire' style air volume meter had been purchased

by research fellow Neil Peterson. To determine the actual

air volumes produced by the previously constructed ‘smelter’ bellows

unit during the October 2021 test, both the normal electric blower

and the bellows were paired to the air inlet piping. The rough

average volumes measured using those bellows was just over 500

Litres per Minute.

This smelter

bellows unit had been built in 2008, as part of the ‘Vinland’

series. It has been used for a number of past smelts, where

either remote locations or a desire for more historic equipment has

required human powered air.

Air system set up, blower on left, bellows to

rear, as used October 2021.

Part of the intent for the June 2022 (#

91 - LAM, Lower & Longer) smelt was to reduce the air

volumes down to be in line with the measurements made during the

October 2021 test (#

90 - Wind and Weathering).

TIME

|

OPERATOR |

LENGTH |

DELIVERY |

% Added |

|

|

|

|

|

| 15:00 |

Schweitzer |

6 |

541 |

50% |

| 15:06 |

Peterson |

5 |

491 |

42% |

| 15:11 |

Markewitz |

1 |

477 |

8% |

|

average |

|

503 |

|

|

weighted |

|

515 |

|

|

|

|

|

|

| 17:06 |

Schweitzer |

4 |

549 |

57% |

| 12:10 |

Peterson |

2 |

559 |

29% |

| 17:12 |

Markewitz |

1 |

542 |

14% |

|

average |

|

550 |

|

|

weighted |

|

551 |

|

|

|

|

|

|

| 19:44 |

Schweitzer |

2 |

532 |

50% |

| 19:46 |

Peterson |

1 |

487 |

25% |

| 19:47 |

Markewitz |

1 |

501 |

25% |

|

average |

|

507 |

|

|

weighted |

|

513 |

|

|

|

|

|

|

| Overall |

average |

|

520 |

|

|

weighted |

|

526 |

|

# 90 - Table 2-1 : Bellows Air Delivery, October 2021

The June bloom yield was significantly higher

than was expected - at 28 %. To that end, the October 2022 smelt was

a repeat of June, using the same

furnace (with repairs), duplicating set up, ore, and process

(as closely as possible).

The furnace built for the June experiment was

basically in good condition, with only two areas needing some

repairs. The material gathered from Norstead at L’Anse aux Meadows

was found to be baked to a loose sandy consistency, so that

rectangular section was replaced with the same clay mix that made up

the rest of the furnace. Some cracking was expected at the boundary

lines, as this fresh addition was exposed to typical smelting

temperatures.

There had been the usual damage to the front

extraction area of the furnace when the slag mass was pulled clear

previously. A number of smaller solid clay construction bricks were

placed to duplicate the existing plinth structure, with one brick

used to fill the space of the original extraction arch. The result

was an arch 11 cm tall by 22 cm wide. There was no tapping arch

made, as it was felt the various gaps between the random selection

of bricks would serve for this purpose.

The copper tuyere was placed back into the

same location as previous, the only significant difference was the

insert distance was increased to 6 cm (from 5 cm proud used last

time), and the base depth (distance below tuyere) increased to 20

cm (from 16 + cm). Fresh clay was added as required to seal the

tuyere in place.

|

|

Damage after October

2021

|

As rebuilt for

October 2022 (early sunlight)

|

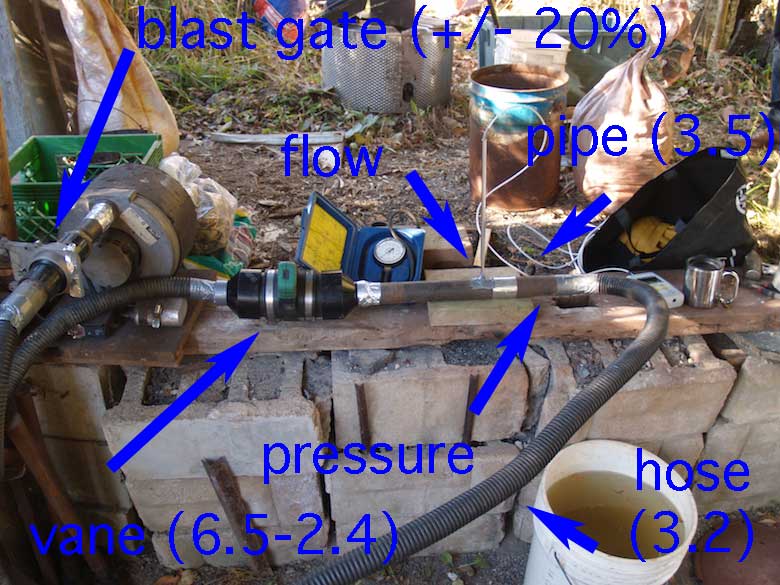

The air inlet system, other than the tuyere and associated fittings,

was slightly different than that used in June. The connections this

time were made via corrugated plastic sump pump hose with a minimum

Internal Diameter of 3.2 cm ( 1 1/4”), replacing the smooth surfaced

flexible metal pipe that had an ID of 5 cm. Although the new

arrangement used two shorter pieces, the total length of the hosing

was about the same as in June.

Air delivery with gauges in place (pipe

diameters given)

In practice, the air flow from the electric

blower was set using the same sliding plate blast gate that

has been employed for the blower source experiments since (at least)

2008. There is a roughly calibrated scale on the plate, marked to

increments of 100 LpM, originally scribed using measurements via a

pocket wind speed anemometer. Given the scale of the marks, the best

accuracy that could be expected here would be roughly 15 %, which

has not been considered critical in past experiments (primarily

since this variation is the same in all cases).

Also included in the instrumentation was a vane

type anemometer (Mastech

MS 6252B), also provided by Neil. This unit is really intended

for measuring air flow inside heating / cooling ducts, and when

confined to a small diameter fitting it's readings have been found

not to conform to the results from other equipment. Also included

was a fitting connected to a (much older) dial style direct pressure

gauge, but this unit is intended for much higher pressure automotive

applications, so barely registers in this system.

The Smelt :

The ore used here was basically the same standard

DD1 analog mix that was used in June. (1) A measurement of of water

content was made for the October batch, with a 100 gm sample baked

for 5 minutes on the top of the furnace to drive out any remaining

water. The ‘bone dry’ weight was 88 gms, a water content of 12 %.

This compares with past measurements, were most typically the water

content has ranged between 8 - 10 % with the same test method.

Although not tested for, it is most likely that the ore batch used

for the June smelt may have had an even lower water content, as it

had been sun dried over at least a full week, with daily conditions

bright and sunny with temperatures into the range of 30 C. (See the

discussion below of moisture content against the top of the

furnace.)

Smelt Team:

Darrell Markewitz - smelt master, extraction

Neil Peterson - lead hand, recording, consolidation

Ryan Kuntze - charcoal, consolidation

Ethan Khan Hafner - ore, consolidation

Max Hafner - materials processing

|

|

(L-R) Ryan, Ethan, Max - breaking sun

dried ore into suitable sized pieces.

|

First addition of rough charcoal, showing

the working area. Instrumentation (not connected yet) in

the foreground, blower to the extreme right. (image by

Lezli Kuntze) |

The start time through preheat phase was a

similar duration, although with a second use the furnace walls would

have been baked dry to partially sintered. Once again the primary

charcoal used was oak. As ore additions were made, the same sequence

of amounts was used as done with the previous experiment (groups

of three, at 1 / 1.5 / 2 / 3 kg each charcoal measure).

It was obvious from the beginning however that

the individual burn rates (time for standard measure) were longer

than the June smelt. (Go to the sequence

data) As calculated over the period of identical ore

additions / total amount of 24.5 kg :

total time

average burn - kg

ore average - kg

June 295 min.

12 min.

11.8 min.

October 391 min.

18.1 min.

16.0 min.

In comparison, the ‘ideal’ burn rate is

considered to be roughly 6 - 8 minutes per kg.

Although there were two new assistants for this

smelt (Ryan and Ethan) their activity was with breaking charcoal and

ore, then during the smelt itself making the required ore and

charcoal additions, under experienced guidance.

Two initial ‘seed’ charges, each one kg, of an

uncertain quality Lexington Limonite ore were made as was also done

in June. These charges were in place of the usual amount of iron

rich slag that are added to accelerate the creation of a working

slag bowl system, a standard method for this team. (2)

|

|

| Ryan adding ore with Max

observing, near the end of the sequence. (image by

Lezli Kuntze) |

Dramatic image of charcoal addition

by Ethan (image by Lezli Kuntze)

|

As was the case in the last test, and as expected

with lower volume air, the slag bowl was initially observed to form

higher than ideal in relation to the tuyere, potentially creating a

problem with rising slag obscuring the air blast. Rather than

tapping off accumulating slag, a steel rod was driven through the

rear portion of the slag bowl from the top of the furnace, allowing

excess slag to drain through into the charcoal fines beneath. This

process was done twice, at 1430 (2 kg seed + 3 kg ore added) and at

1606 (2 kg seed + 7.5 kg ore added). Later in the smelt, the furnace

would self tap (‘incontinent’) several times. Generally this smelt

ran pretty much as normal, beyond the significantly increased (and

expected) burn rates.

It was decided to leave the extraction process in

experienced hands. As was done in June, the extraction arch and

lower plinth below was opened, then the remaining charcoal fines

scrapped clear to expose the bottom of the slag bowl. Again, the

bowl was firmly attached to the lower furnace walls. To break this

clear, the log ‘thumper’ was used to pound the bloom down with the

encasing slag bowl to break this all clear, The loose mass was then

pulled free out the arch, which did result in more slag bowl

remaining attached around the bloom as it was lifted to the

compaction stump.

Because of the greatly increased time of the main

smelt sequence ( over 6 1/2 hours other than the more typical 3 - 4)

and short November daylight, it was fully dark by the time

extraction was undertaken. With first time workers Ryan and Ethan

using unfamiliar sledges, breaking off encrusting slag and initial

bloom compaction was not as efficient as might be desired. Working

in darkness can be difficult for even experienced workers, and

certainly any estimation of temperature via heat colour was

distorted.

|

Compaction - short video by Max Hafner

|

After initial clearing of slag, the bloom mass

was rushed back to the workshop, and further compression was

attempted using the hydraulic press. In truth by this point the

metal was far too cold, certainly for true compacting, even through

simple mechanical adhesion. The bloom had a very ‘crumbly’ texture

as well, so the net result was considerable fracturing. It was

decided to break up and cut the mass into several pieces, primarily

so both Ryan and Ethan could have smaller sections to keep as a

reward for their efforts.

With the resulting pieces and any fragments

larger than ‘half walnut’ (collected magnetically), the total bloom

weight was 5 kg, compared to the analog ore input of 24.5 kg,

a final yield of 20 %. Using a quick spark test, the metal

showed some slight carbon content, estimated to be about half way

between carbon free iron and mild steel (at 0.2% C), so potentially

about 0.1 % C. (3)

Air Flow Measurements :

Measurements of air flow were taken at a number

of points over the main smelting sequence. This unlike experiment #

90, when continuous readings were inputted directly into a lap top

computer. One continuing problem is converting the gauge readings

(with instruments intended for other purposes) into our desired

units of Litres per Minute :

Time

|

Mastech

|

LpM

|

Omega

|

LpM

|

1122

|

3.8

|

654

|

|

|

1148

|

3.9

|

671

|

|

|

1301

|

4.0

|

688

|

6.15

|

486

|

1 kg ore in stack

|

|

|

|

|

1649

|

|

|

5.1

|

403

|

about 3 kg ore in stack

|

|

|

|

|

1823

|

4.16

|

791

|

5.25

|

416

|

about 4 kg ore in stack

|

|

|

|

|

The previously measured plate setting was for 500

LpM (considered to be at best within 15 %), the set of measurements

from the Omega unit are considered to be most likely. It would be

expected that air flow would be reduced as more and more ore is

added into the same stack height of burning charcoal.

Discussion :

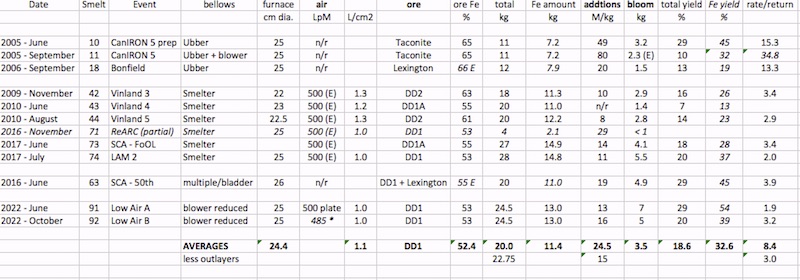

The past work of this team has been focused on

working systems based primarily on Viking Age bloomery iron

smelting. How close to these original processes it is possible to

match is effected by the limits of archaeological prototypes, and

significantly by differences in the materials that are available due

to the physical location in Southern Ontario, Canada.

Over the years there have been a number of smelts

using hand powered bellows based on possible Norse design : an early

oversized ‘Ubber-Bellows’,

the more manageable ‘smelter’

bellows, and configurations using ‘blacksmith’

sized units :

In so much as many of these smelts were carried

out at various ‘remote’ locations (with less control over

environment and general support), it might be expected that the

overall results might also be somewhat random :

- The furnaces themselves are fairly consistent in size and overall

layout, all of the ‘Norse

Short Shaft’ type, almost all at 25 cm interior diameter and

typically 40 + cm of working stack height.

- There is some variation in ore iron concentration, but the bulk of

tests are using variations on the red iron oxide (Fe2O3) analog

developed and the primary material used after 2008, with roughly 53

% Fe most typical.

- The total ore amounts used show more variation, but most smelts

added between 20 - 28 kg, with the average (discounting the first

three low volume tests and the single limited test) at 23 kg.

- When considering air delivery via a pumped bellows, produced

volume will vary considerably both by individual operators

(differences in physical abilities), and also over the long duration

of a smelt (through simple fatigue).

It is important to note the estimated (E) value

for so many of the LpM volumes indicated. This is an amount

estimated from the figures measured during the October 2021 test,

placed in retrospect (there were no actual measurements made at the

indicated experiments). This limits the amount of the indicated

litres per square centimetre (at tuyere cross section) figure. With

bellows use, this could be expected to be somewhat lower than the

‘ideal’ figure of 1.2 - 1.5 L/cm2 suggested by Sauder &

Williams. (4) normally sought in other smelts.

With so many of the other variables (furnace size

and layout, ore content and amounts) being fairly consistent, it is

hard not to attribute the large variation in ‘addition rate’ (time

in minutes for one kilogram of ore, as an average over the entire

smelt sequence) to differences in air delivery *method*, rather than

just volume, over the duration of an individual smelts listed above.

For experiment # 92, air volume measurements were made at periodic

points over the smelt, with readings from the two instruments.

Weather Impact ?

- On June 25, it was bright and sunny, and extremely hot at 20 C at

the start, plus 30 C by mid day, falling to about 23 C by the end of

the smelt

- On October 29, it was bright and sunny, and ‘seasonal’ at 0 C at

the start, 14 C by mid day, falling to about 6 C by the end of the

smelt.

It has been seen however, that other smelts

undertaken out of doors without any cover have not illustrated any

particular impact of environmental conditions on to the quality of

input air :

- Smelt

# 14 (February 2006) was at Traverse City Michigan when day

time temperatures only reached -15 C, with 29 kg of taconite ore

into a 13.6 kg bloom (47% yield). A number of smelts have been

undertaken with air temperatures into the 35 C range (June / July),

down to the 5 C range (March / November) , with no observable impact

on burn rates or resulting yields. It should be noted that compared

to the internal operating temperature of these furnaces at plus 1350

C, variations in input air temperature such a small fraction as to

be insignificant.

- Smelt

# 47 (April 2011) was at Bristol, Rhode Island with almost

constant rain or drizzle. Ore used was a combination of primarily

low iron content Limonite (mainly producing considerable slag) with

11 kg higher iron ores (black oxide and Hematite), producing a 2.2

kg bloom (20% yield against those better ores). This was a teaching

event however, and a number of major problems had occurred over the

sequence. Other smelts have been undertaken at ocean shores (

# 11 / #

44 / #

74) but as these smelts depended on bellows driven air, the

possible effect of damp air can not be determined. Smelts are almost

always set to fixed schedules, either annual dates or set months in

advance, and are conducted ‘rain or shine’. Even so, on reflection,

few have been undertaken with rainy weather for comparisons, also

noting that environmental conditions (beyond the exceptional) are

rarely recorded.

There exists the potential for charcoal to absorb

moisture from the environment over time :

- The charcoal used in June was mainly recently purchased, where it

had been stored inside, with a weight per standard measure of 1.8 kg

- The charcoal used in October had been purchased in mid June, and

stored outside for four months, with a weight per standard measure

of 1.8 kg

In truth however, the considerable amount of

waste heat at the top of a correctly designed furnace, will serve to

bake out any moisture contained in freshly added charcoal, well

before it descends far enough to react with the available oxygen in

the stack. Temperatures at the top of a furnace (so here + 40 cm

above the tuyere) have been regularly measured in the range of 600

C. Because of this, moisture content of the charcoal via atmospheric

absorption is not considered to have any impact on the smelting

process.

Conclusions (?)

Comparing the June smelt (# 91) against October

(# 92), especially with references to other experiments utilizing

lower air volumes (admittedly all using bellows variations), it

would appear the ‘odd’ result is in fact June, with that yield of 28

%. The results of the October smelt at 20 % more closely approach

the values produced from those other experiments. At the limits of

casual observation, there are only three differences between the two

‘Low Air’ smelts :

- Source air temperature was roughly 30 C in June, roughly 10 C in

October.

- Charcoal used in June was ‘bone dry’, while than in October had

absorbed a slight amount of moisture.

- Air from the blower delivered in a smooth interior pipe at 5 cm ID

in June, a corrugated minimum 3.3 cm ID in October.

This last element, at least on first glance,

appears the only accountable difference. The measurements of air

volumes as recorded are made within the sealed air input system

however, so should still reflect the actual flow of air into the

furnace.

The last possibility is some difference in

physical method by the two groups of workers (charcoal and ore

additions) between the two smelts. In June, these tasks were mainly

carried out by individuals who had long (decades) experience. In

October, these were first time workers, but under the supervision

and guidance of those same senior experimenters.

After considerable discussion and reflection, it

would appear that the results of the October experiment are the

more dependable, in terms of judging the effects of low volume

air into this standard furnace layout and materials. It may be that

a combination of factors, individually so small to barely register,

added up to enough effect to produce the exceptional results in

June.

The difference between the constant blast

produced by blowers, and the pulsing flow produced by Norse styled

twin bellows still remains to be further explored. (5)

Notes:

1) Simple geography of South Central Ontario precludes the

availability of any nature iron ores, including primary bog iron

ore. The Dark

Dirt series of analogs uses commercially available iron oxide

powders as the base, with a donation of a large quantity of red

oxide / Fe2O3 as the DD1 the main type for these experiments. A

batch is prepared for each smelt, a 22.5 kg bag is mixed with 2.5 kg

of whole wheat flour, plus enough water to create a paste about the

consistency of mayonnaise. This is then spread on to trays to about

1.5 cm thick, which are placed outside in the sun to dry. In off

season / foul weather, the drying process may be assisted by placing

the trays under infra-red heat lamps. Individual batches can be

expected to vary slightly in water content (as discussed), with

total amounts normally varying primarily through spilling) between

23 to 25 kg.

2) In June there was no tap slag from previous smelts available, and

some of the stockpiled (poor quality) Lexington Limonite had been

substituted. The method of quickly establishing a working slag bowl

by making initial charges (2 - 3 kg) of black iron rich slag was

developed by Michael Nissen of Denmark, and communicated

during the 2008 ‘Iron

in Thy’ symposium.

3) Judging carbon content by observing the sparks through grinding

is at best only a rough approximation, as much experience as

anything. Compounding this is the known variation of carbon through

a raw bloom, where the original top surface commonly has a higher

carbon amount than the bottom side. Testing broken pieces will

further result in random results. The process of welding up a bloom

into a consistent bar will also both blend and modify the starting

carbon contents.

4) Sauder, L., & Williams, S., 2002, A Practical

Treatise on the Smelting and Smithing of Bloomery Iron,

Historical Metallurgy 36 (2), (available as pdf) https://s3.amazonaws.com/images.icompendium.com/sites/eliz2406/sup/3694971-A-practical-treatise-on-the-smelting-and-smithing-of-bloomery-iron.pdf

5) Peterson, N., 2021, A lot of Hot Air: Exploring Air

Production in Viking Era Bellows, presented at the 12th

Experimental Archaeology Conference - EAC12 World Tour (publication

pending)

An important consideration is separating the

specific operation of Norse twin bellows from other human powered

air delivery systems. Norse bellows will produce a pulsing air

supply, which would also be the case for still earlier drum or bag

bellows systems, or the roughly contemporary Chinese box bellows.

The historically later ‘Great Bellows’ (mid 1300’s) has a ‘double

action’ mechanism, where a moving first chamber supplies air to a

second delivery chamber, thus actually creating a constant air

blast. The same result will be found with any system that uses a

collecting air bladder as a second stage, regardless of the initial

air input. Unfortunately, too many living history based teams do not

clearly describe exactly what equipment they are using when stating

‘used a bellows’.